Lazer Kaynak Makinesi - Eksiksiz Kılavuz

Lazer Kaynak Makinesi - Eksiksiz Kılavuz

Geleneksel kaynak stratejileri sıradan elektrikli kaynak ve argon ark kaynağı gibi için yeterli değil endüstriyel çelik kaynak üretimi. Bunun bunların geleneksel kaynak yöntemlerinin üretimine çelik|| ||keskin kenarlı ve kusurlu kaynaklar.

Lazer kaynağı masaüstü yeni bir tür kaynak bilgisayar cihazı kaynağı yapan ekstra estetik olarak çekici çatlak ve gözeneksiz.

Bunu bilimi çoğu metali aşırı hızda ve sarf malzemesi olmadan kaynaklamak için kullanabilirsiniz. Ve bilim yenilikler yapmaya devam ederken, el tipi kaynak makineleri ve kaynak temizlik makineleri gibi çok işlevli kaynak makineleri mevcuttur.

Hadi kaynak makinelerini daha büyük birlikte inceleyelim sonraki!

Lazer kaynağı nedir?

Lazer kaynak makineleri nasıl çalışır?

Lazer kaynak makinesinin özellikleri

Lazer kaynak teknolojisinin artıları ve eksileri

Lazer kaynak makinelerinin sınıflandırılması

Lazer kaynak makinelerinin yapısı

Lazer kaynağının en iyisini etkileyen faktörler

Lazer kaynağı nedir?

In easy terms, Laser welding is a method for becoming a member of metallic substances with laser light. The welding velocity is additionally very excessive due to the very focused warmness supply of the laser beam. Laser welding is used to weld two same substances as some distance as possible. It is a non-contact welding manner in which the cloth is usually melted via the laser and the melted cloth solidifies to obtain the welding effect. The welding effects fluctuate from the laser welding laptop to the laser welding machine.

Nasıl seçilir

The preference of laser welding computer is carefully associated to the thickness of the fabric you are welding. There are two kinds of lasers in frequent use today: pulsed and non-stop lasers.

Pulsed lasers:

The excellent desire for welding skinny metals

Mainly used for welding jewelry, skinny steel tubes, plates, etc.

Continuous laser

The exceptional desire for welding thick metals

Longer carrier life

Ideal for welding thick metals, e.g. development steel

The excessive rate of non-stop lasers

Tendency to over-weld gaps, distortion, and even direct melting of the metallic when welding skinny metals

How laser welding machines work

The laser welder desktop works with the aid of focusing the laser beam onto the welding head by using an optical element, the total manner is very complex. In easy terms, the pump mild absorbs uncommon earth ions in the optical fiber and the uncommon earth electrons are then excited to greater excitation strength levels. The ensuing laser mild is then transmitted thru the optical fiber to the welding head. Of course, the extra precise outgoing mild system is past my knowledge, so if you are fascinated you can seek advice from with our engineers online.

In easy terms, the precept of welding is to use the excessive temperature of the laser to immediately melt the steel and then solidify it inside seconds to entire a quickly weld. This is the cause why we can't contact the welded floor with our arms without delay after welding. There is a lot of warmth left on the floor of the steel that has simply been welded and direct contact can injury the skin.

Lazer kaynak makinesinin özellikleri

Small welding seams and excessive precision

The welding machines are greater flexible, in particular handheld laser welding machines.

The laser welding computing device has low environmental requirements

Suitable for welding refractory materials, e.g. titanium alloys

No contact welding, no section loss

Pros and cons of laser welding technology

Intelligent laptop manipulate and a excessive diploma of automation make it simpler to manipulate the machine

Durable welding seam built-in into the steel part

Fast welding speed, appropriate for industrial mass production

One profitable pass, no secondary processing required

Suitable for nearly all metals, so broadly used in dentistry, pcb, electronics, car parts, and different industries

Small weld seams and easy surfaces

Non-contact welding, no cloth loss

Precise welding of metallic components of all shapes, angles, and positions

Particularly appropriate for welding small precision parts, such as earrings, pcb, etc.

Of course, laser welding machines additionally have some cons:

satın almak için pahalı ve aşırı yenileme maliyetler

Improper coping with may also end result in raised welds, which want to be polished manually afterward

Not appropriate for welding incredibly reflective metals

Classification of laser welding machines

Above we have stated the classification of lasers for laser welder machines. Normally we can classify them in accordance to the laser source.

Currently, we can classify metallic laser welding machines in accordance to the laser supply into three types:

CO2 laser welding machines

CO2 laser welding machines normally use alternating currents to excite a gasoline combination in the tube. This kind of laser supply belongs to the class of non-stop lasers and is appropriate for welding thick metals and non-metals.

Fiber laser welding machines

It produces a small and sharp beam of mild that is succesful of penetrating. It is consequently appropriate for welding thick metals and is one of the most correct welding strategies for welding metals.

YAG laser welding machine

This is a much less energy-efficient welder and is appropriate for welding small parts.

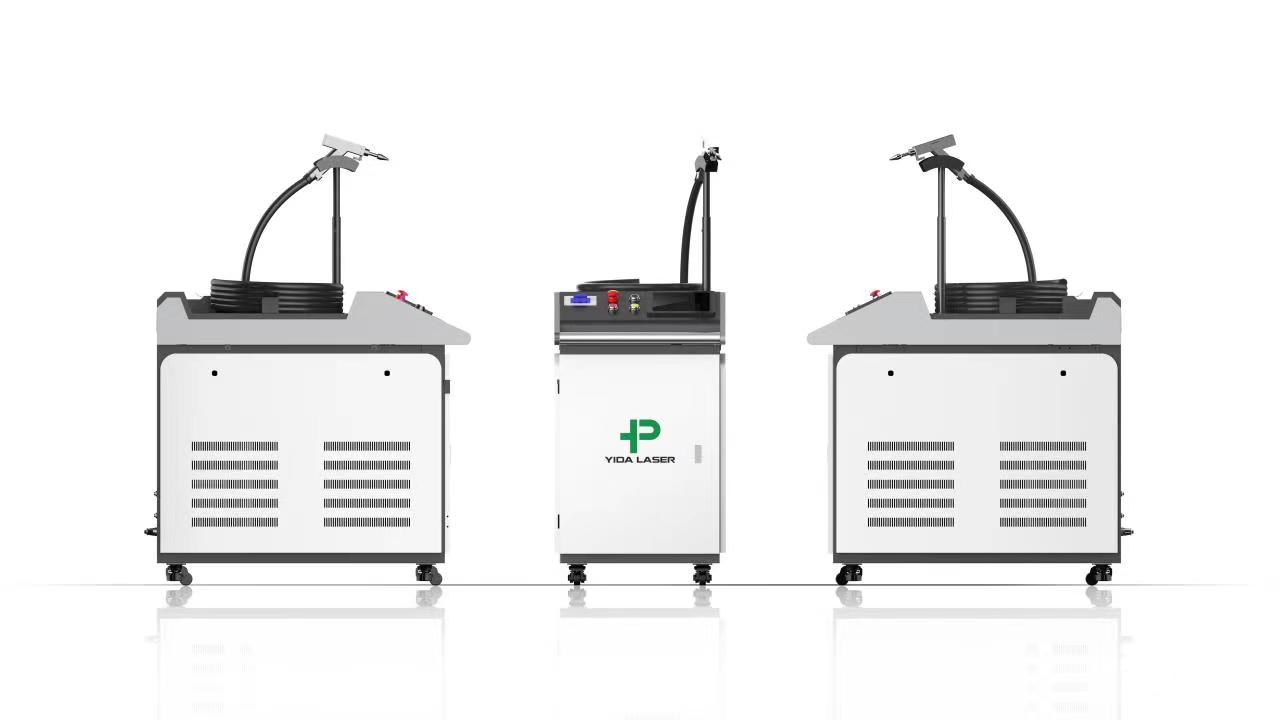

Lazer kaynak makinelerinin yapısı

The Laser welder computing device consists of four important parts:

The welder

The primary feature of the welder is to produce the laser beam for welding, consisting of the electricity supply, the manage system, and the laser.

Cooling system

Like the laser cutter, the laser welder desktop is additionally geared up with a cooling system.

Fixture

Are you questioning why a laser welding laptop desires a fixture? Except for handheld steel laser welding machines, most welding machines are outfitted with clamps to preserve the welded components in place.

Observation system

The viewing gadget of the welding computer helps the real-time commentary of the workpiece, which is beneficial for watching the positioning throughout the welding system and the end result after welding.

Factors affecting the first-class of laser welding

Several elements have an effect on the effectiveness of laser welding and you want to pay more interest to the following parameters earlier than the use of the welding machine.

Equipment Quality

The overall performance of the welding desktop has a direct have an effect on on the best of the steel weld. The spot impacts the width and depth of the weld. In prevalent the decrease the beam sample order, the smaller the spot, i.e. the smaller the spot diameter. Smaller spots supply higher welding results. However, the spot dimension need to no longer be too small. Otherwise, the spot will without difficulty be contaminated in the course of the welding process. I suggest that you pick out a laser beam with a diameter of between 0.2 and two mm.

Again, the first-rate of the laser and the output strength will have an effect on the fine of the weld. The longer the wavelength, the decrease the absorption and the much less favorable it is for metallic welding.

Quality of the metallic weld

The first-rate of the welded section additionally has a direct have an impact on on the welding result. If the metallic section is rusty or the weld floor is now not clean, this can make laser welding greater difficult. After welding, lumps or gaps may also appear, or even if there is too plenty metallic in the weld, the welding might also no longer be completed.

Welding parameters

The right welding parameters make sure a greater secure welding performance. First of all, test the pulse frequency, which is inversely proportional to pulse energy. The greater the frequency, the decrease the welding efficiency.

The pulse waveform is additionally a very vital parameter and you want to trade the parameters in time relying on the kind of metallic to be welded.

Choosing a right focal factor function is additionally of fantastic significance for the welding process.

The relationship between welding energy and welding depth is proportional, about 0.7 times. However, the quicker the welding speed, the much less warmness enter will end result in shallower welding depth.

Protective gas

The motive of the defensive gasoline is to shield the workpiece from oxidation and to facilitate the well timed blowing away of metallic vapors. It additionally helps to cool the weld metallic in time and speeds up the completion of the weld.